When you need a small, lightweight bearing to rotate a heavy load with minimal friction, machined type needle roller bearings are often the appropriate choice. Thanks to their low sectional height, outer ring with stable high rigidity and high- or low-speed rotation capabilities, they can be ideal for a variety of general-purpose applications and machine profiles. Additional advantages of machined needle roller bearings include:

- Lower rotational torque for exceptional mechanical efficiency.

- Minimal inertia when the load is put into motion.

- Smaller spacing pitch between needles, which makes them particularly suitable for oscillating motion.

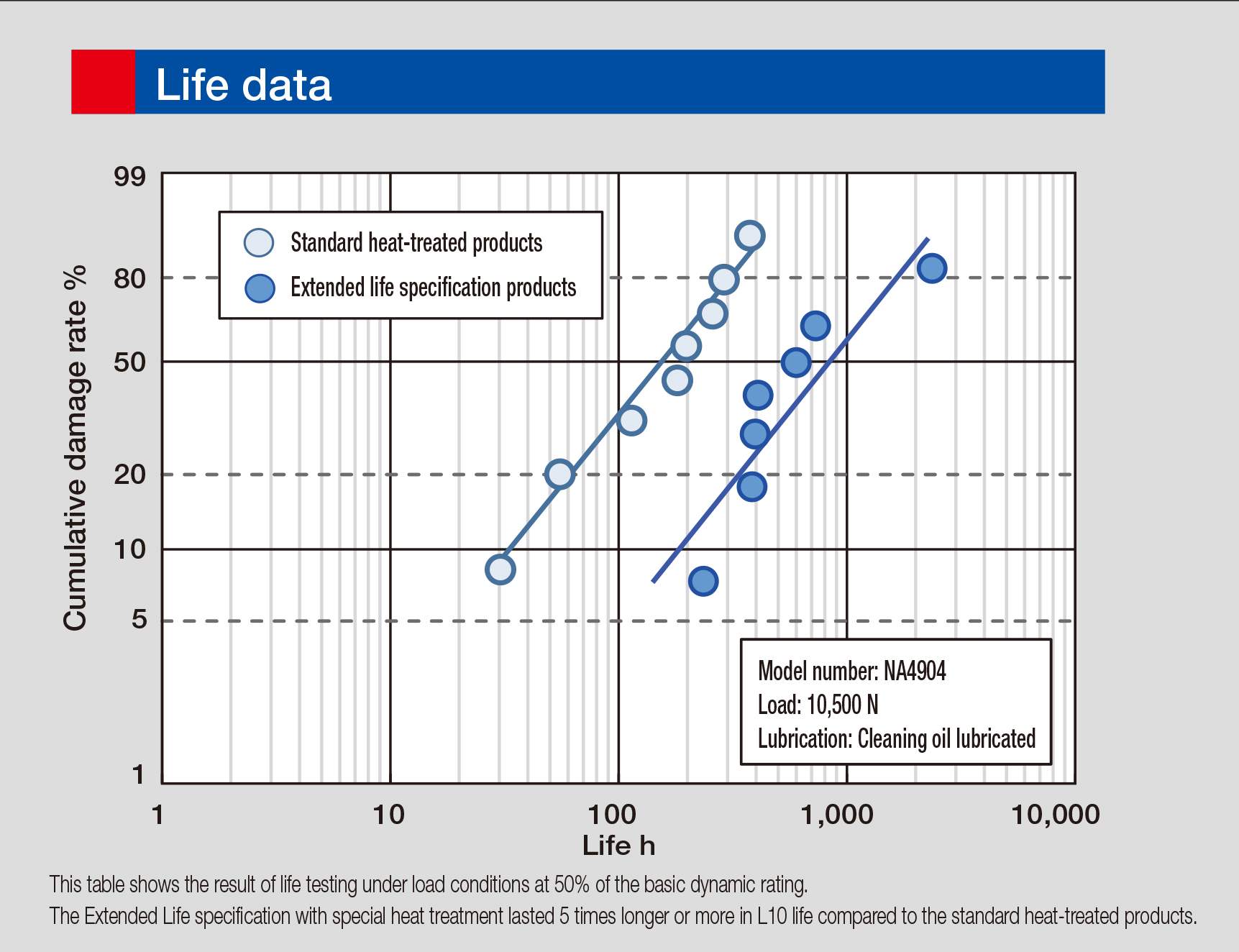

However, some heavy duty applications can wear out these bearings faster, requiring them to be replaced more often, until now. IKO has introduced a new machined needle roller bearing — the Extended Life Specification bearing — that delivers both performance and an extended operating life up to five times longer than standard needle roller bearings.

Extended Life Specification machined needle roller bearings receive a special heat treatment that enhances their surface hardness and toughness to minimize damage over time. The bearings can achieve long lifetimes even under high load or when the lubrication is contaminated with foreign substances. In fact, when life-tested under load conditions at 50 percent of the basic dynamic load rating, IKO’s Extended Life Specification with special heat treatment lasted five times longer when compared to the standard heat-treated products.